Guitar

As I describe here, things have slowed down considerably since this summer. It quite typical to me (and probably many others), that planning is easy, but when I get to the point of actually making the things I've been planning, the progress goes down.

In the meantime, until I get the motivation for taking the T-beam guitar some steps further, I might as well plan even more. ...and consider alternative methods for future guitars.

One of the issues I prefer to think of is the possible tuner systems for headless guitars. On Building the Ergonomic Guitar, there's much discussion around how to make a headless tuner system. See e.g. here and here.

I'd like to add another possible principle to the discussion: Using a bicycle brake cable tensioner. It is normally used to tighten the brakes of a bicycle by turning the nut with the rubber ring seen here (click the images for a better view). Since the threaded, cylindrical part of the tensioner has a flat area which fits a hole of the same shape in the brake arm, it will not turn (but only slide) when the nut is rotated. On a bicycle, as seen here

(click the images for a better view). Since the threaded, cylindrical part of the tensioner has a flat area which fits a hole of the same shape in the brake arm, it will not turn (but only slide) when the nut is rotated. On a bicycle, as seen here  , the outer cable stops at the tensioner, and the inner cable goes through it and is fastened on the other arm of the brake.

, the outer cable stops at the tensioner, and the inner cable goes through it and is fastened on the other arm of the brake.

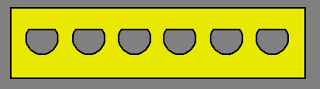

When using it as a guitar tuner, the string passes through the cylinder (the part with the outer thread) and the total of six tuners/tensioners should be mounted in a brace with six holes of the shape that allows the cylinders to slide, but not to rotate

and the total of six tuners/tensioners should be mounted in a brace with six holes of the shape that allows the cylinders to slide, but not to rotate  . By turning the individual nuts (the part with the rubber ring), the strings are tuned.

. By turning the individual nuts (the part with the rubber ring), the strings are tuned.

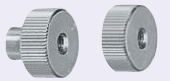

Of course, there's no need to use dedicated bicycle brake cable tensioners. It might be better to make the tuners from pieces of threaded rod with a hole drilled through them plus some knurled knobs such as these . Choosing three knobs of each of the two types shown in the picture would even allow for a staggered placement of the knobs, in turn allowing bigger knobs than with an in-line configuration.

. Choosing three knobs of each of the two types shown in the picture would even allow for a staggered placement of the knobs, in turn allowing bigger knobs than with an in-line configuration.

I'd expect it to look like this.

It seems to me to be one of the simplest solutions to the problem of making cheap, accurate and reliable tuners for a headless guitar. I may have overlooked some problems with the principle, so prototyping must be the next step. Once I've finished the T-beam guitar.

- New Tuner, Bridge, Jack And Tubing

This last month I've been improving some details of the testbed guitar: The tuner has been changed to my slider-based design. It is mounted on an angled plate ensuring that the strings have sufficient break angle over the saddles. The angle also...

- Coarse Tuners Part 3

As mentioned in this post, I am trying to make a set of coarse tuners, compact and light, for use with my fine tuning bridge, allowing me to ditch the headstock. The first version used T-nuts, but this time, I made a brass plate with threaded holes to...

- Coarse Tuners Part 2

As described in an earlier post, I've tried to make a compact set of coarse tuners to go with the fine tuners on my Schaller 456 fine tuning bridge, so I could reduce the headstock and loose the big and heavy traditional tuners. The earlier attempt...

- Using Traditional Tuners For Headless Designs

A post on this blog contains some nice sketches of headless guitars with traditional tuners mounted behind the bridge. Some designs even had holes through the body for the tuners. That looked good, but it might be difficult to get a good hold of the tuners...

- Bridge And Tuners For The Headless Design

Having settled on a headless design, one of the next questions was which bridge and tuners to use. A small number of bridges with built-in tuners already exist, e.g. the ABM or the Steinberger. Unfortunately, they are all fairly expensive, and it was...

Guitar

More beating around the bush

As I describe here, things have slowed down considerably since this summer. It quite typical to me (and probably many others), that planning is easy, but when I get to the point of actually making the things I've been planning, the progress goes down.

In the meantime, until I get the motivation for taking the T-beam guitar some steps further, I might as well plan even more. ...and consider alternative methods for future guitars.

One of the issues I prefer to think of is the possible tuner systems for headless guitars. On Building the Ergonomic Guitar, there's much discussion around how to make a headless tuner system. See e.g. here and here.

I'd like to add another possible principle to the discussion: Using a bicycle brake cable tensioner. It is normally used to tighten the brakes of a bicycle by turning the nut with the rubber ring seen here

(click the images for a better view). Since the threaded, cylindrical part of the tensioner has a flat area which fits a hole of the same shape in the brake arm, it will not turn (but only slide) when the nut is rotated. On a bicycle, as seen here

(click the images for a better view). Since the threaded, cylindrical part of the tensioner has a flat area which fits a hole of the same shape in the brake arm, it will not turn (but only slide) when the nut is rotated. On a bicycle, as seen here  , the outer cable stops at the tensioner, and the inner cable goes through it and is fastened on the other arm of the brake.

, the outer cable stops at the tensioner, and the inner cable goes through it and is fastened on the other arm of the brake.When using it as a guitar tuner, the string passes through the cylinder (the part with the outer thread)

and the total of six tuners/tensioners should be mounted in a brace with six holes of the shape that allows the cylinders to slide, but not to rotate

and the total of six tuners/tensioners should be mounted in a brace with six holes of the shape that allows the cylinders to slide, but not to rotate Of course, there's no need to use dedicated bicycle brake cable tensioners. It might be better to make the tuners from pieces of threaded rod with a hole drilled through them plus some knurled knobs such as these

I'd expect it to look like this.

It seems to me to be one of the simplest solutions to the problem of making cheap, accurate and reliable tuners for a headless guitar. I may have overlooked some problems with the principle, so prototyping must be the next step. Once I've finished the T-beam guitar.

- New Tuner, Bridge, Jack And Tubing

This last month I've been improving some details of the testbed guitar: The tuner has been changed to my slider-based design. It is mounted on an angled plate ensuring that the strings have sufficient break angle over the saddles. The angle also...

- Coarse Tuners Part 3

As mentioned in this post, I am trying to make a set of coarse tuners, compact and light, for use with my fine tuning bridge, allowing me to ditch the headstock. The first version used T-nuts, but this time, I made a brass plate with threaded holes to...

- Coarse Tuners Part 2

As described in an earlier post, I've tried to make a compact set of coarse tuners to go with the fine tuners on my Schaller 456 fine tuning bridge, so I could reduce the headstock and loose the big and heavy traditional tuners. The earlier attempt...

- Using Traditional Tuners For Headless Designs

A post on this blog contains some nice sketches of headless guitars with traditional tuners mounted behind the bridge. Some designs even had holes through the body for the tuners. That looked good, but it might be difficult to get a good hold of the tuners...

- Bridge And Tuners For The Headless Design

Having settled on a headless design, one of the next questions was which bridge and tuners to use. A small number of bridges with built-in tuners already exist, e.g. the ABM or the Steinberger. Unfortunately, they are all fairly expensive, and it was...