Guitar

As described in an earlier post, I've tried to make a compact set of coarse tuners to go with the fine tuners on my Schaller 456 fine tuning bridge, so I could reduce the headstock and loose the big and heavy traditional tuners. The earlier attempt in the form of a locking nut wasn't succesful, but now I think I'm on to something.

As described in an earlier post, I've tried to make a compact set of coarse tuners to go with the fine tuners on my Schaller 456 fine tuning bridge, so I could reduce the headstock and loose the big and heavy traditional tuners. The earlier attempt in the form of a locking nut wasn't succesful, but now I think I'm on to something.

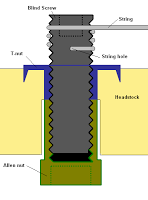

I've installed my own coarse tuners, each consisting of a blind screw, a T-nut and an allen nut (a.k.a. an internal wrenching nut). In the blind screw, a hole is drilled for the string to go through, just like the peg of an ordinary tuner.

To tune up the guitar, you turn the blind screw clockwise with an allen key until you reach the approximate tone. Then you fasten it by tightening the allen nut on the back of the headstock. The rest of the tuning is done with the fine tuner at the bridge.

To tune up the guitar, you turn the blind screw clockwise with an allen key until you reach the approximate tone. Then you fasten it by tightening the allen nut on the back of the headstock. The rest of the tuning is done with the fine tuner at the bridge.

One of the beautiful things about it is that when you tighten or loosen the string by turning the set screw, the height of the string over the fingerborad stays the same, since it rests in the screw's thread. And the pull of the string tightens the allen nut against the T-nut, securing the string even more.

The best thing about it is, it seems to work perfectly. And it's much smaller and lighter than ordinary tuners, so it's a good solution if you want to build a headless guitar - or convert an existing guitar to one. You'll have to leave a little bit of headstock for the T-nuts, but that's not much. And you might want it anyway to stop your fretting hand from sliding off the neck.

On my own guitar I've mounted the tuners on the very end of the headstock. The reason is that I'll be using the other sections of the headstock for experimentation with alternatives to the T-nuts. A set of threaded inserts and a brass plate with threaded holes are some of the things I want to try. Next experiment will probably be threaded inserts mounted on the next section of the headstock. And I imagine that when I have reached the last section of the headstock, next to the nut, I'll know which of the solutions I prefer.

On my own guitar I've mounted the tuners on the very end of the headstock. The reason is that I'll be using the other sections of the headstock for experimentation with alternatives to the T-nuts. A set of threaded inserts and a brass plate with threaded holes are some of the things I want to try. Next experiment will probably be threaded inserts mounted on the next section of the headstock. And I imagine that when I have reached the last section of the headstock, next to the nut, I'll know which of the solutions I prefer.

Drilling the string holes in the blind screws was a pain. I only got two made before I had dulled or broken my drill bits. I'll have to buy some new ones and do it right. That's the reason why the remaining four strings in the picture go to traditional tuners.

Btw, I imagine that if you add some loctite or similar to increase friction, you might be able to do away with the allen nut. Afaik, there also is a substance called "peg dope". I have to get some and try if the tuner can hold the string without the allen nut.

- Coarse Tuners Part 5

The coarse tuners that I made for the black SG with the Schaller fine tuning bridge were - after all - too troublesome to string and adjust. I've made another attempt, this time consisting of - a hex screw going through the head plate, - an acorn...

- New Tuner, Bridge, Jack And Tubing

This last month I've been improving some details of the testbed guitar: The tuner has been changed to my slider-based design. It is mounted on an angled plate ensuring that the strings have sufficient break angle over the saddles. The angle also...

- New Tuner Design

In the previous post, I described my intention of creating a playable testbed for experiments with different pickups. It turned out to be nice to play, so I improved it with a strap horn and the acrylic body from my t-beam bass. As it turned out, it was...

- A Locking Nut That Didn't Work

Since I put the T-beam guitar on hold for a while, I bough a cheap Gibson SG copy for various experiments. One of the first things I wanted to try out was a tuning system, which uses a locking nut in combination with a Schaller 456 fine tuning bridge...

- A Different Tuner System For Headless Designs

The guitar I'm planning at the moment might be the first in a series. If it turns out well and the building process is fun (the planning sure is), I expect to build another one. And probably then another. And so on. If the guitar turns out sounding...

Guitar

Coarse Tuners part 2

I've installed my own coarse tuners, each consisting of a blind screw, a T-nut and an allen nut (a.k.a. an internal wrenching nut). In the blind screw, a hole is drilled for the string to go through, just like the peg of an ordinary tuner.

One of the beautiful things about it is that when you tighten or loosen the string by turning the set screw, the height of the string over the fingerborad stays the same, since it rests in the screw's thread. And the pull of the string tightens the allen nut against the T-nut, securing the string even more.

The best thing about it is, it seems to work perfectly. And it's much smaller and lighter than ordinary tuners, so it's a good solution if you want to build a headless guitar - or convert an existing guitar to one. You'll have to leave a little bit of headstock for the T-nuts, but that's not much. And you might want it anyway to stop your fretting hand from sliding off the neck.

Drilling the string holes in the blind screws was a pain. I only got two made before I had dulled or broken my drill bits. I'll have to buy some new ones and do it right. That's the reason why the remaining four strings in the picture go to traditional tuners.

Btw, I imagine that if you add some loctite or similar to increase friction, you might be able to do away with the allen nut. Afaik, there also is a substance called "peg dope". I have to get some and try if the tuner can hold the string without the allen nut.

- Coarse Tuners Part 5

The coarse tuners that I made for the black SG with the Schaller fine tuning bridge were - after all - too troublesome to string and adjust. I've made another attempt, this time consisting of - a hex screw going through the head plate, - an acorn...

- New Tuner, Bridge, Jack And Tubing

This last month I've been improving some details of the testbed guitar: The tuner has been changed to my slider-based design. It is mounted on an angled plate ensuring that the strings have sufficient break angle over the saddles. The angle also...

- New Tuner Design

In the previous post, I described my intention of creating a playable testbed for experiments with different pickups. It turned out to be nice to play, so I improved it with a strap horn and the acrylic body from my t-beam bass. As it turned out, it was...

- A Locking Nut That Didn't Work

Since I put the T-beam guitar on hold for a while, I bough a cheap Gibson SG copy for various experiments. One of the first things I wanted to try out was a tuning system, which uses a locking nut in combination with a Schaller 456 fine tuning bridge...

- A Different Tuner System For Headless Designs

The guitar I'm planning at the moment might be the first in a series. If it turns out well and the building process is fun (the planning sure is), I expect to build another one. And probably then another. And so on. If the guitar turns out sounding...