Guitar

The guitar I'm planning at the moment might be the first in a series. If it turns out well and the building process is fun (the planning sure is), I expect to build another one. And probably then another. And so on. If the guitar turns out sounding horribly and/or the building is hell, I guess that'll be it. But that hasn't happened yet, so for the moment, I'm happily planning features for future models.

As mentioned earlier, I've settled for the Schaller fine-tuning bridge for the first version of the T-beam. This will avoid a number of potential problems and make the construction more straightforward. I am fine with that. For the next version, however, I have a sleek and efficient tuner design in mind.

The system consists of six arms mounted with one end on a shaft below the top flange of the T-beam. Approximately two thirds to the far end from the shaft, the string attaches to the arm (after going over the bridge and through a hole in the top flange) and is secured either by its ball end or by a screw. The latter solution will allow me to use the ball end at the nut, eliminating the need for a locking nut.

For each arm, a screw is mounted through the top flange. The end of the screw presses down on the arm. Tightening the screw results in pressing down the arm and tightening the string. If the aluminium is strong enough, the threads will be made directly in the top flange. If not, I'll insert some threaded steel or brass bushings.

The picture shows the guitar with one arm only. It is supposed to have six - one for each string.

By selecting steeper or shallower thread for the screws or various lengths of the arm, one can decide how much adjustment is needed for a given change in tuning. An obvious idea is to have a greater ratio for the thicker strings, since it takes more force to tune them.

My rough measurements say that it takes about 4 mm (0,16 inch) to tune the string an octave. That means that there is lots of room for the travel of the arm, even with a relatively thin body.

The idea goes well with using a T-beam, since it uses the top flange for mounting the arm and screw. But actually, I think it can be made as a modification for a wooden guitar as well - all you have to do is route out a cavity for the tuner system and mount it all on a steel or aluminium sheet.

- Coarse Tuners Part 2

As described in an earlier post, I've tried to make a compact set of coarse tuners to go with the fine tuners on my Schaller 456 fine tuning bridge, so I could reduce the headstock and loose the big and heavy traditional tuners. The earlier attempt...

- New Tuners

I've always wanted to try out my a particular form of tuners for headless guitars and basses. They work by having a scew pulling a brass block in which the ball end of the string is mounted. The main inspiration was Jeff Turpin's tuners; drawings...

- A Locking Nut That Didn't Work

Since I put the T-beam guitar on hold for a while, I bough a cheap Gibson SG copy for various experiments. One of the first things I wanted to try out was a tuning system, which uses a locking nut in combination with a Schaller 456 fine tuning bridge...

- Bridge And Tuners For The Headless Design

Having settled on a headless design, one of the next questions was which bridge and tuners to use. A small number of bridges with built-in tuners already exist, e.g. the ABM or the Steinberger. Unfortunately, they are all fairly expensive, and it was...

- Background - Why And How

Over the last years, I've become more and more interested in building guitars rather than (just) playing them. I never got around to actually building anything, but I took a couple of guitars apart and put them together again. I also discovered, that...

Guitar

A different tuner system for headless designs

The guitar I'm planning at the moment might be the first in a series. If it turns out well and the building process is fun (the planning sure is), I expect to build another one. And probably then another. And so on. If the guitar turns out sounding horribly and/or the building is hell, I guess that'll be it. But that hasn't happened yet, so for the moment, I'm happily planning features for future models.

As mentioned earlier, I've settled for the Schaller fine-tuning bridge for the first version of the T-beam. This will avoid a number of potential problems and make the construction more straightforward. I am fine with that. For the next version, however, I have a sleek and efficient tuner design in mind.

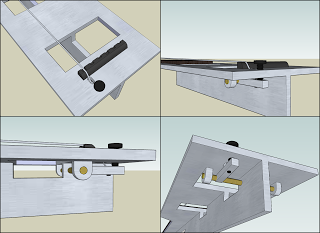

The system consists of six arms mounted with one end on a shaft below the top flange of the T-beam. Approximately two thirds to the far end from the shaft, the string attaches to the arm (after going over the bridge and through a hole in the top flange) and is secured either by its ball end or by a screw. The latter solution will allow me to use the ball end at the nut, eliminating the need for a locking nut.

For each arm, a screw is mounted through the top flange. The end of the screw presses down on the arm. Tightening the screw results in pressing down the arm and tightening the string. If the aluminium is strong enough, the threads will be made directly in the top flange. If not, I'll insert some threaded steel or brass bushings.

The picture shows the guitar with one arm only. It is supposed to have six - one for each string.

By selecting steeper or shallower thread for the screws or various lengths of the arm, one can decide how much adjustment is needed for a given change in tuning. An obvious idea is to have a greater ratio for the thicker strings, since it takes more force to tune them.

My rough measurements say that it takes about 4 mm (0,16 inch) to tune the string an octave. That means that there is lots of room for the travel of the arm, even with a relatively thin body.

The idea goes well with using a T-beam, since it uses the top flange for mounting the arm and screw. But actually, I think it can be made as a modification for a wooden guitar as well - all you have to do is route out a cavity for the tuner system and mount it all on a steel or aluminium sheet.

- Coarse Tuners Part 2

As described in an earlier post, I've tried to make a compact set of coarse tuners to go with the fine tuners on my Schaller 456 fine tuning bridge, so I could reduce the headstock and loose the big and heavy traditional tuners. The earlier attempt...

- New Tuners

I've always wanted to try out my a particular form of tuners for headless guitars and basses. They work by having a scew pulling a brass block in which the ball end of the string is mounted. The main inspiration was Jeff Turpin's tuners; drawings...

- A Locking Nut That Didn't Work

Since I put the T-beam guitar on hold for a while, I bough a cheap Gibson SG copy for various experiments. One of the first things I wanted to try out was a tuning system, which uses a locking nut in combination with a Schaller 456 fine tuning bridge...

- Bridge And Tuners For The Headless Design

Having settled on a headless design, one of the next questions was which bridge and tuners to use. A small number of bridges with built-in tuners already exist, e.g. the ABM or the Steinberger. Unfortunately, they are all fairly expensive, and it was...

- Background - Why And How

Over the last years, I've become more and more interested in building guitars rather than (just) playing them. I never got around to actually building anything, but I took a couple of guitars apart and put them together again. I also discovered, that...